Utilizing digitally fabricated reinforced concrete modules, we are proposing the creation of a prefabricated, modular system that allows the air traffic control tower design to be quickly adapted to site height constraints. Organized around a central elevator shaft, the modules would rotate one degree for each foot of elevation gain. The resultant forms are unique air traffic control towers, each with a distinct form in relation to their height, sustainably created and adapted to each site.

Each module stacks upon one another to create a tight reinforced shell. This shell wraps around the stair and elevator of the tower. The resulting envelope provides support for the control cab, meeting, and electrical room spaces. Additionally, this envelope creates a passive cooling and heating opportunity called “the stack effect” and provides a framework for power generating photovoltaic glass.

Services

Architecture

Engineering

Planning

Sustainable Design

Services

Architecture

Engineering

Planning

Sustainable Design

Utilizing digitally fabricated reinforced concrete modules, we are proposing the creation of a prefabricated, modular system that allows the air traffic control tower design to be quickly adapted to site height constraints. Organized around a central elevator shaft, the modules would rotate one degree for each foot of elevation gain. The resultant forms are unique air traffic control towers, each with a distinct form in relation to their height, sustainably created and adapted to each site.

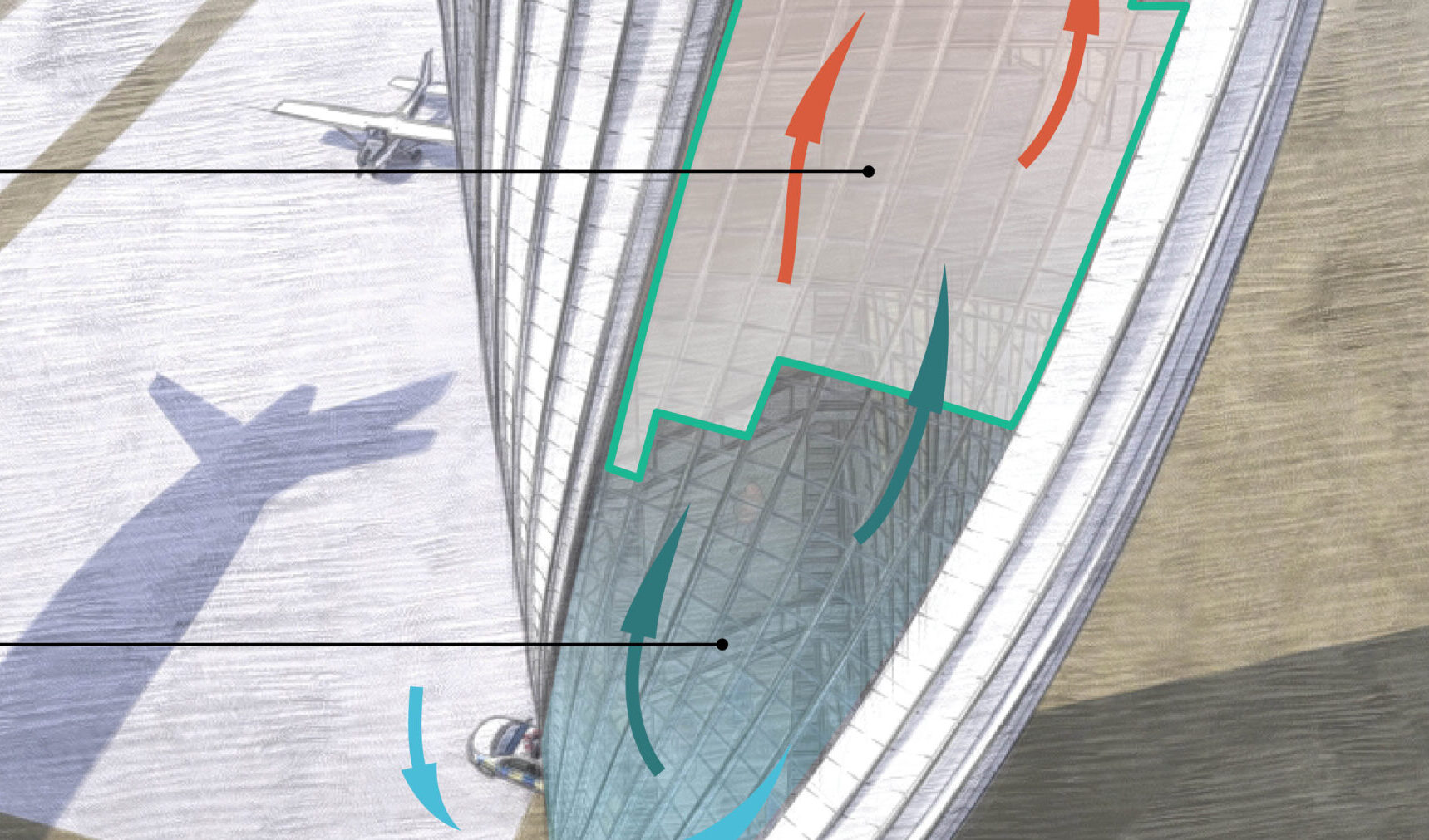

Each module stacks upon one another to create a tight reinforced shell. This shell wraps around the stair and elevator of the tower. The resulting envelope provides support for the control cab, meeting, and electrical room spaces. Additionally, this envelope creates a passive cooling and heating opportunity called “the stack effect” and provides a framework for power generating photovoltaic glass.

A critical requirement of the design challenge is the need for each Air Traffic Control Tower to meet variable height and site requirements. Our design addresses these needs in two ways. First, the modular design allows for stackablility. This stackability allows for a tower that can be designed with a cab floor as low as 60’-0” and up to a height 119’-0”. Any range of heights in-between can be met. Secondly, the use of digitally manufactured reinforced precast concrete ensures that the same design can be utilized in a wide range of climates. Much less susceptible to corrosion than steel or aluminum, concrete will weather harsher climates be er than other common building materials.

Additionally, increased support can be designed into the concrete shell where required for seismic and hurricane site conditions.

Several sustainable design strategies are incorporated into the design. Due to the amount of applicable surface area for photovoltaic glass, a “net-zero” building could potentially be achieved.

PHOTOVOLTAIC GLASS SKIN –

Photovoltaic glass is transparent glass that produces electricity. Safety glass is embedded with photovoltaic modules which generate power from the sun. The power generation from

this glass would be able to offset the power costs needed to operate the building.

STACK EFFECT COOLING –

Stack effect cooling occurs when thermal differences in air temperature are created. The tower design utilizes this effect by opening up the base of the tower to the glass and concrete shaft. As the upper air heats the lower air is forced up through the building decreasing demand on the buildings HVAC systems.

Advancements in digital design and fabrication in recent years have expanded the speed at which construction on projects can be executed. Due to the rapid rate of construction on and overall scope, this project is a perfect candidate for prefabricated construction. Each concrete module would be fabricated in a shop, loaded onto a truck, and shipped to the job site where the contractor would then assemble the parts.